C.E.R.E.S. Remediation Products focuses on innovative and economical solutions for the sustainable remediation of heavy metals, chlorinated solvents, and petroleum hydrocarbon. Our products are intended for remediation of Soil and Groundwater using heavy metals sequestration and stabilization, in situ chemical reduction (ISCR) with Zero Valent Iron (ZVI), Surfactant Enhanced Remediation (SER), and bioremediation for petroleum remediation (petroleum treatment solution electron acceptors) and chlorinated solvent remediation applications (emulsified vegetable oil, lactates or other soluble electron donors).

In 2015, C.E.R.E.S. was started by experienced remediation chemistry experts and former environmental consultants in the U.S. to offer more effective engineered to order solutions for heavy metals contamination (i.e. Metals Treatment Solution (MTS®). We have successfully treated many dozens of projects with MTS® over the years and look forward to bringing our capabilities and chemistry to you for your projects.

C.E.R.E.S. is also a provider of common remediation chemistries such as ferrous sulfate, magnesium sulfate, magnesium oxide and hydroxide, different phosphate chemistries, chemical buffers for pH control, oxygen scavengers for ZVI or anaerobic bioremediation applications, and carbon substrates for chlorinated solvent bioremediation. Additional chemistries available include a variety of sulfides, natural and impregnated zeolite and injectable powder activated carbon (iPAC). C.E.R.E.S. ZVI is manufactured in the US and abroad and sources the best available iron from all over the world to ensure the best In Situ Chemical Reduction (ISCR) performance and remediation results for our customers internationally. We support many customers internationally and have done so successfully since we started.

We are committed to continuous quality control and research and development to improve upon our chemistries for commonly known as well as emerging contaminants such TCP, PFAS and others in order to offer a better performing, more economical, and more sustainable and resilient solution compared to currently available options. For PFAS compounds we are offering high quality injectable powder activated carbon for sequestration that is combined with other reagents to resolve commingled and mixed contaminant soil and groundwater remediation applications.

We are eager to support customers with Added Value Services including Treatability Studies, Pilot Test design support, or turn key services for pilot and full scale remediation services. If you are looking for a lump sum and guaranteed remediation contract option, we are confident and have the experience to see your remediation project through to completion.

Manufacturer of Soil and Groundwater Remediation Products

CERES Corporation is a remediation products manufacturer focusing on innovative and economical solutions for the sustainable remediation of heavy metals, petroleum and chlorinated organic contamination.

We assist you along the entire path as part of our regular customer support services. Whether you are doing a desktop conceptual design, a bench study or a preliminary cost estimate, we are here to help you be successful. We will review your conceptual site model and conduct a data gap evaluation for the remediation approaches you are considering.

We offer free treat-ability studies for customers in-house and with independent laboratories and supply samples of our products if you want to do it on your own. We understand the importance of performance verification to help develop your pilot test or full scale remediation.

Turn key services are available to pilot test the reagent at your site including bench scale testing, site data gap evaluations (required), workplans, permitting, on-site execution by injection or soil mixing, performance assessment, detailed reporting and regular communication along the way.

Turn key services are available for full scale remediation implementation including all the above activities and full scale design workplans, scheduling, permitting, on-site execution by injection and or soil mixing, performance assessment and detailed reporting.

C.E.R.E.S. Zero Valent Iron (ZVI) are highly reactive micro-scale iron powders and granules for in situ chemical reduction of chlorinated solvents, metals, and nitrates. ZVI is produced by different methods including water atomization, reduced iron (Sponge Iron), and hydrometallurgical processes with iron (Fe) content up to 99% and no appreciable surface oxides. Many soil and groundwater remediation projects have been successfully completed since 2015 after single injection events. Experience and results matter most!

BioGeoChemical Reduction (BGCR) BGCR combines physical, chemical, and microbiological (i.e. biogeochemical) processes to create strong reducing conditions that achieve rapid contaminant destruction by abiotic and biotic reduction.

Advanced proprietary and site specific engineered formulation of stabilization chemistries for use in chemical sequestration and immobilization of heavy metals as a stand alone solution or in combination with stabilization and solidification applications.

C.E.R.E.S. offers high quality and high surface (e.g. 1,000 m2/g) area powder activated carbon (iPAC) for remediation application in soil and groundwater by adsorption of organic contaminants, PFOS /PFOA (iPAC-PF), and some heavy metals (e.g. Hg) or in combination with other chemical reductive and biotic reduction reagents.

PTS is comprised of essential micro- and macro-nutrients and a complete source of electron acceptors required for the proliferation of indigenous microorganisms and accelerated biodegradation of petroleum hydrocarbons, fuel oxygenates, polyaromatic hydrocarbons, and petroleum remediation in soil, groundwater, and surface water environments.

Petroleum Treatment Bacteria (PTBac) contains a blend of facultative hydrocarbon degrading bacteria specifically chosen for the petrochemical industries applicable to both aerobic and anaerobic conditions. This product provides a significant boost to biodegradation rates when combined with PTS to rapidly achieve treatment goals and reduce the overall costs of remediation.

Surfactant enhanced remediation product comprised of an all-natural solution of the most advanced sustainable and biodegradable surfactant blend resulting in accelerated emulsification and desorption of petroleum hydrocarbons, fuel-oxygenates, polycyclic aromatic hydrocarbons, chlorinated benzene and many more contaminants in soils, groundwater, and surface water environments.

Ferrous Sulfate has been used for chromium remediation in the same way that calcium polysulfide has for some decades. It is sometimes a component of MTS® blended chemistries for multi-metal contaminated soils and sold as is (Ferrous Sulfate) to customers who wish to use it on their own.

MgSO4 is a good source of sulfate for various applications in the environment. C.E.R.E.S. maintains inventory of MgSO4 at 99% purity and with anticaking agents when desired and can provide customer guided blended products.

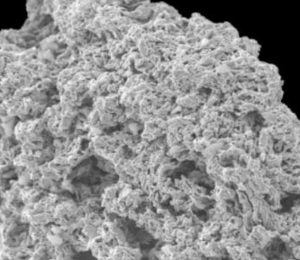

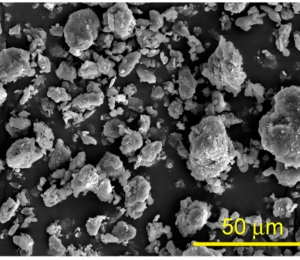

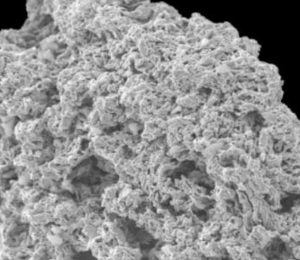

C.E.R.E.S. Zero Valent Iron (ZVI) are highly reactive micro-scale iron powders and granules for in situ chemical reduction of chlorinated solvents, metals, and nitrates. ZVI is produced by different methods including water atomization, reduced iron (Sponge Iron), and hydrometallurgical processes with iron (Fe) content up to 99% and no appreciable surface oxides.

C.E.R.E.S. Zero Valent Iron (ZVI) are highly reactive micro-scale iron powders and granules for in situ chemical reduction of chlorinated solvents, metals, and nitrates. ZVI is produced by different methods including water atomization, reduced iron (Sponge Iron), and hydrometallurgical processes with iron (Fe) content up to 99% and no appreciable surface oxides. Many soil and groundwater remediation projects have been successfully completed since 2015 after single injection events. Experience and results matter most!

Petroleum Treatment Bacteria (PTBac) contains a blend of facultative hydrocarbon degrading bacteria specifically chosen for the petrochemical industries applicable to both aerobic and anaerobic conditions. This product provides a significant boost to biodegradation rates when combined with PTS to rapidly achieve treatment goals and reduce the overall costs of remediation.